Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The Hidden Heroes: How Engine Bearings Power Your Vehicle's Performance

The Silent Guardians of Your Engine: A Complete Guide to Bearings

Why Engine Bearings Matter More Than You Think

Within the beating heart of every internal combustion engine lies an unsung hero - the engine bearing. These precision components work tirelessly to transform violent combustion forces into smooth rotational motion while preventing catastrophic metal-on-metal contact. Unlike flashy performance parts that grab attention, bearings operate in obscurity, making their failure one of the most expensive and preventable forms of engine damage.

The Physics of Survival: How Bearings Withstand Engine Fury

Internal combustion engines present one of the most challenging environments in mechanical engineering. Temperatures swing from sub-zero cold starts to 250°F+ operation, while combustion pressures exceed 1,000 PSI in modern turbocharged engines. Conventional rolling element bearings collapse under these conditions due to:

Cyclic loading from alternating combustion pulses

Impact forces during piston reversals

Oil film breakdown under extreme pressures

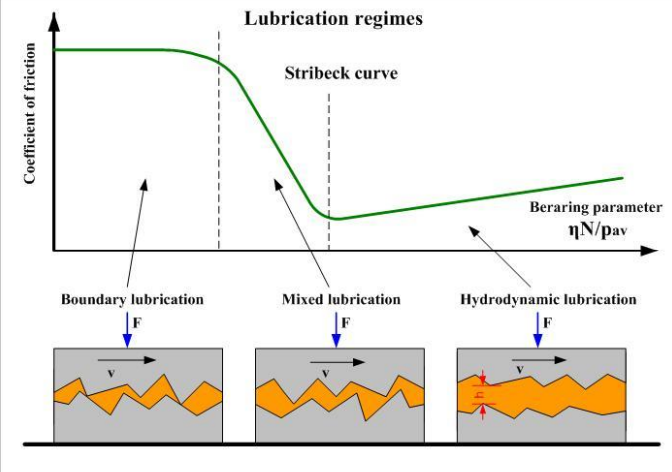

Sliding bearings solve these challenges through intelligent pressure distribution. Their secret lies in the hydrodynamic lubrication principle - maintaining a protective oil wedge between moving surfaces even under 10,000+ PSI loads.

Mastering the Bearing Trinity: Three Critical Types

1. Crankshaft Main Bearings: The Engine's Spinal Column

Positioned at strategic points along the engine block, main bearings perform three vital functions:

Support rotating crankshaft weight (up to 50 lbs in V8 engines)

Absorb combustion forces transmitted through connecting rods

Maintain critical oil clearance of 0.001-0.003 inches

Advanced designs incorporate flange bearings with integrated thrust washers to control axial movement - crucial in engines with high-pressure oil pumps or gear-driven accessories.

2. Connecting Rod Bearings: The Piston's Dancing Partner

These crescent-shaped marvels endure the engine's most brutal forces:

Peak combustion pressures exceeding 2,000 PSI

Inertial forces at 8,000 RPM piston reversals

Shear stresses from 180° directional changes

Modern connecting rod bearings use tri-metal construction:

Steel backing for structural integrity

Copper-lead intermediate layer for conformability

Electroplated babbitt surface for embeddability

3. Small End Bushings: The Wrist Pin Whisperers

Often overlooked but critical for piston alignment, these bronze bushings:

Allow oscillating wrist pin movement

Prevent piston skirt scuffing

Maintain oil control ring efficiency

Oil System Synergy: The Lifeblood of Bearing Survival

Bearings and lubrication systems work in perfect harmony through:

Feature Function

Grooved upper bearings Distribute oil to crank journals

Cross-drilled crankshafts Supply rod bearings under pressure

Microscopic surface textures Maintain oil film during start-stop cycles

Failure Patterns Every Mechanic Should Recognize

Watch for these early warning signs:

Low oil pressure at idle (worn clearances)

Knocking sounds during acceleration (fatigue spalling)

Copper-colored oil (bearing overlay failure)

Future-Proof Designs: Where Bearing Technology Is Headed

Emerging innovations promise longer bearing life:

Diamond-like carbon (DLC) coatings for zero-wear surfaces

Smart bearings with embedded wear sensors

3D-printed conformal cooling channels

Maintenance Secrets for Million-Mile Bearings

Extend bearing lifespan with these pro tips:

Always prime oil filters after changes

Use synthetic oil with ZDDP additives

Warm engines gently before hard acceleration

From tiny 200cc motorcycle engines to massive marine diesels, bearings remain the universal linchpin of mechanical motion control. Their continued evolution enables modern engines to achieve previously unimaginable power density and longevity. By understanding these critical components, enthusiasts and technicians alike can better appreciate - and protect - the hidden marvels that make rotational power possible.